In hardware manufacturing, small engineering errors can lead to costly rework, delays, and potential product failures. These often stem from fragmented vendor coordination and workflow mismatches. Adopting turnkey pcb assembly minimizes such errors, ensuring smooth and repeatable outcomes from prototype to mass production.

Engineering Error Impact

Engineering errors—such as incorrect component placement, footprint mismatches, or outdated BOM revisions—can severely affect production yield. Each rework cycle costs valuable time, materials, and engineering effort. In competitive markets where hardware teams face strict launch deadlines, every delay erodes the advantage of innovation. Reducing these errors at the root level requires an integrated manufacturing and design feedback system.

How Turnkey Solves Mismatches

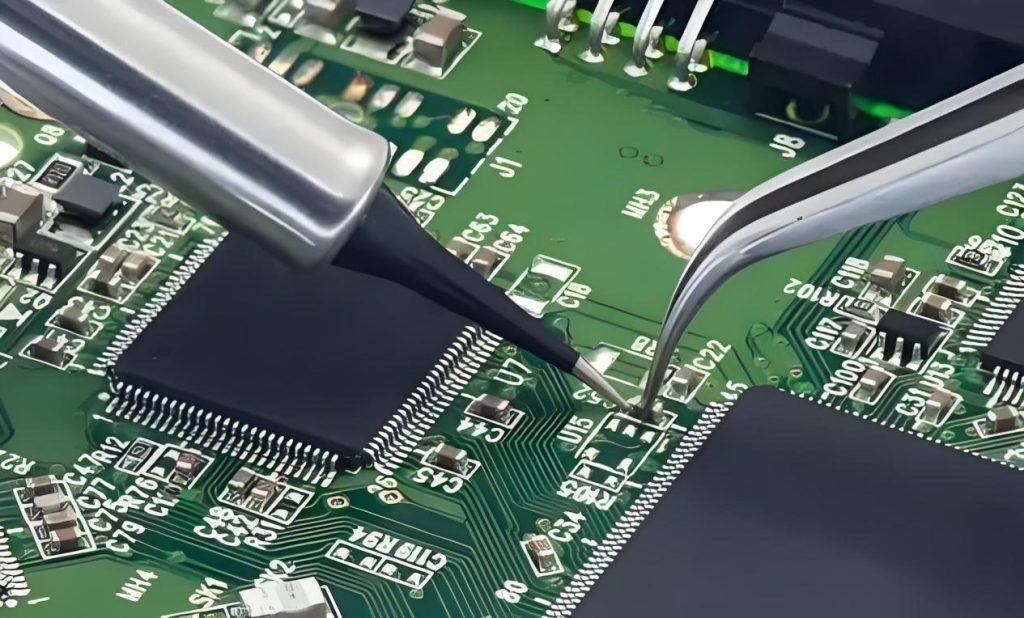

A turnkey PCB assembly process unites procurement, fabrication, assembly, and testing under one provider. This integration ensures real-time communication and flags issues before they become costly errors.

This unified approach also prevents errors caused by version inconsistencies in CAD files, component substitutions, or fabrication parameters—common pain points in multi-supplier setups.

BOM Accuracy Advantages

A BOM is error-prone in PCB production. When managed by different parties, discrepancies can cause setbacks. Turnkey providers centralize BOM management, validating each component before production.

Automated BOM checks give engineers early warnings on shortages or obsolescence, helping keep accuracy and supply continuity.

DFM/DFA Integration

One of the core strengths of engineering-support turnkey assembly is early integration of Design for Manufacturability (DFM) and Design for Assembly (DFA) feedback. In a turnkey workflow, the manufacturer reviews designs upfront and recommends optimizations that improve production quality and reduce rework risk.

By integrating DFM/DFA at the pre-production stage, design errors like insufficient pad spacing, poor trace routing, or solderability issues are corrected before the first board is built. This proactive engineering collaboration minimizes downstream surprises during assembly.

Repeatability from Prototypes to Production

Consistency between prototype builds and production batches is a hallmark of a strong turnkey system. With a single provider overseeing both, process parameters—such as stencil design, reflow profiles, and component placement programs—remain consistent throughout the product lifecycle.

This repeatability is vital for scaling, ensuring that tested prototypes match final products without extra adjustments.

Risk Reduction

By centralizing design validation, component sourcing, and manufacturing, turnkey PCB assembly for reducing engineering errors and rework dramatically cuts overall project risk. The single-vendor model reduces the number of potential failure points, improves traceability, and provides end-to-end accountability. As a result, engineering teams experience fewer surprises, less rework, and more predictable project outcomes.

Why FastTurn Excels

FastTurn PCB has built its reputation on precision-driven turnkey solutions. With in-house PCB fabrication, SMT assembly, and engineering review teams, FastTurn ensures every project benefits from proactive DFM analysis, real-time BOM verification, and consistent process control.

Whether it’s a small prototype batch or a large-scale production run, FastTurn’s integrated workflow reduces engineering friction, ensures first-pass yield success, and delivers measurable time-to-market improvements.

Conclusion

Engineering errors and rework threaten hardware projects. Turnkey PCB assembly unifies design, sourcing, and manufacturing, offering integrated engineering support, DFM/DFA optimization, and consistent management. FastTurn PCB is a reliable partner that ensures quality, speed, and cost control for production-ready results.