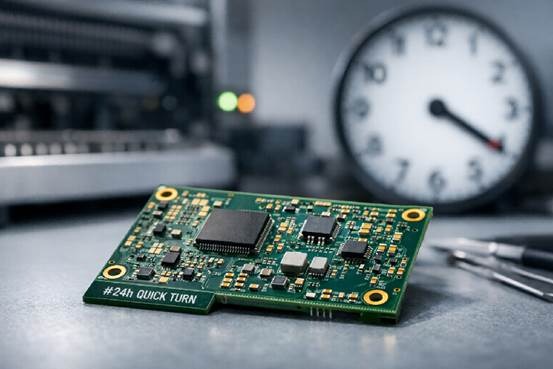

In electronics, time is critical. Product launches, prototypes, and engineering validation often run on tight schedules. Any delay can stall a project. That’s why engineers and startups trust 24 hour quick turn PCB services to deliver working boards in as little as one day.

This article explains what “quick turn” really means, when to use it, and how to make sure your PCB project is ready for a true 24-hour turnaround.

What Does 24-Hour Quick Turn Really Mean?

A 24-hour quick turn means your PCBs are fabricated—or sometimes assembled—within one business day. These fast builds are only possible when design data and materials are ready before production.

Most manufacturers can finish up to 4–6-layer FR-4 boards in this time, with standard finishes like ENIG or OSP. More complex designs, such as HDI or high-frequency boards, may take 48–72 hours. To qualify for same-day service, files should be submitted early with all Gerber, BOM, and pick-and-place data approved.

When You Should Choose a 24-Hour Build

Quick turn fabrication suits time-sensitive projects—engineering validation, demo prototypes, urgent replacements, or pre-production builds.

If you need both PCB and component assembly, combining fabrication with quick turn assembly ensures a smooth transition from production to testing. This approach avoids supplier delays and helps engineers receive assembled, tested boards in 24–48 hours.

What You Can Expect in a 24-Hour Window

A 24-hour build works best with standard, well-prepared configurations.

- PCB fabrication: up to 6 layers, FR-4 material, common surface finishes (ENIG/OSP), and standard copper weights.

- Assembly services: high-speed SMT placement, 3D AOI inspection, X-Ray for BGAs and QFNs, and basic functional testing.

- Certifications: Most reliable manufacturers operate under ISO 9001, IPC, and UL standards, ensuring consistent quality even in rush orders.

These services are common in medical devices, automotive, telecom, and consumer hardware industries, where speed and reliability are crucial.

What Affects Lead Time and Cost

Even with a 24-hour promise, lead time and cost depend on several factors:

- Data completeness: Gerber, BOM, and CPL files must be final and error-free.

- Design complexity: More layers, tighter trace widths, or controlled impedance all add time.

- Material choice: Special laminates or thicker copper require longer processing times.

- Component sourcing: Availability of parts directly affects assembly speed.

- Testing needs: ICT or functional testing may extend the total cycle time.

Manufacturers like FastTurn PCB offer full- and partial-turnkey options. Full turnkey means they handle component sourcing, assembly, and testing—ideal for cutting communication and ensuring speed.

DFM and DFX: The Checklist for First-Pass Success

Before you hit “submit,” review your design for manufacturability (DFM) and assembly (DFX). A clean, consistent design can save hours in engineering review and avoid rework.

- Keep trace width and spacing within standard tolerances.

- Verify via size, annular rings, and solder mask clearance.

- Confirm stackup and impedance targets early with your supplier.

- Check part orientation and polarity in your placement files.

- Add sufficient test pads for debugging and in-circuit testing.

- Use consistent reference designators between BOM and layout.

A few minutes spent on this checklist can mean the difference between a 24-hour success and a costly re-spin.

How to Order Without Delays

Here’s a simple 7-step flow to achieve a same-day or next-day PCB turnaround:

- Verify your design rules and impedance stackup.

- Generate and double-check Gerber, BOM, and CPL data.

- Choose standard materials and finishes that support fast fabrication.

- Confirm component availability or approve substitutes.

- Upload all files before the manufacturer’s cutoff time.

- Approve the engineering review promptly.

- Track fabrication, SMT assembly, and shipment.

Companies like FastTurn PCB streamline this process with an online quote system and dedicated engineering support. Their team handles fabrication, component sourcing, and assembly in one workflow to save valuable time.

How to Choose the Right Quick Turn Partner

Not all “24-hour” claims mean the same thing. When comparing vendors, check both technical capabilities and support quality.

Hard factors: ISO and UL certifications, modern SMT equipment, 3D AOI/X-Ray inspection, and proven yield rates.

Soft factors: responsive communication, flexible component sourcing, and transparent lead-time commitments.

The best partners combine fast engineering feedback with consistent production quality. A good 24 hour quick turn pcb partner should deliver both speed and confidence — not surprises.

Real-World Benchmarks

A typical 24-hour service covers 1–4-layer prototype PCBs with same-day shipment, while small-batch assembly may take 48 hours. For 8–10 layers or HDI boards, expect 3–5 days. The key is to align design expectations with the factory’s quick-turn capabilities.

Many engineers start with prototypes and scale to small production runs using the same supplier. This continuity helps maintain design consistency and traceability through every iteration.

Avoid These Common Pitfalls

Even experienced designers can miss small details that delay production. Watch out for:

- Incomplete or mismatched BOM and CPL data.

- Missing test points or unclear reference designators.

- Overly tight spacing or unverified impedance.

- No early discussion on special materials or finishes.

- Ignoring logistics or customs time for international shipping.

Double-checking these details can ensure your 24 hour quick turn pcb order ships on time.

Get Your 24-Hour Build Right the First Time

Fast, reliable, and precise — that’s the promise of true quick-turn service. Whether you need prototype fabrication or full turnkey assembly, choose a partner that understands both engineering and the pressure to meet time-to-market goals.

Get a rapid quote and start your next build today with FastTurn PCB. Their 24-hour service combines quality manufacturing, in-house assembly, and expert support—helping teams bring ideas to life, faster.