Introduction

In the fast-paced world of manufacturing and packaging, efficiency and reliability are crucial. One piece of equipment that plays a vital role in streamlining operations is the vertical packaging machine. These machines are widely used across industries such as food, pharmaceuticals, and consumer goods due to their ability to automate packaging processes, reduce labor costs, and maintain product quality. Selecting the right vertical packaging machine, however, requires careful consideration of multiple factors, including the expertise of VFFS machine manufacturers, machine specifications, and the unique needs of your production line. This guide will provide practical insights into how to choose the best vertical packaging machine for your business.

Understanding Vertical Packaging Machines

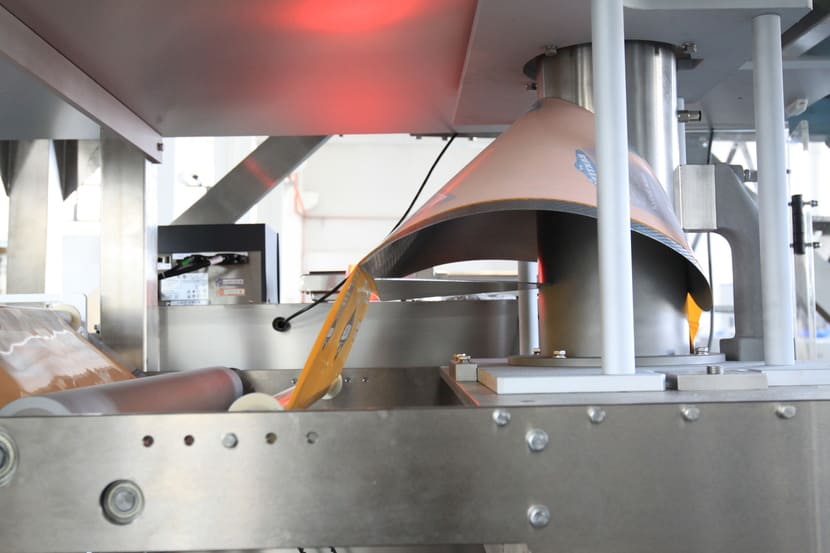

Vertical packaging machines, often referred to as VFFS machines, are designed to automate the process of filling and sealing products in bags or pouches. Unlike horizontal machines, vertical packaging machines operate by feeding products from the top into a forming tube, where the packaging material is shaped, filled, and sealed. This vertical orientation allows for high-speed operation and is particularly effective for products like grains, snacks, powders, liquids, and small hardware items.

The primary advantage of vertical packaging machine is their versatility. Many machines can handle multiple types of packaging formats, including pillow pouches, gusseted bags, and stand-up pouches. Furthermore, these machines often come with programmable settings, enabling precise control over bag length, filling volume, and sealing temperature. This ensures consistent product presentation, reduces material waste, and minimizes errors that can occur in manual packaging processes. By understanding the core functionalities of vertical packaging machines, businesses can make informed decisions when evaluating different models and VFFS machine manufacturers.

Key Features to Look for in a Vertical Packaging Machine

When selecting a vertical packaging machine, it is essential to assess the features that align with your production requirements. One critical factor is the machine’s speed and efficiency. High-speed machines can significantly boost productivity, allowing businesses to meet increased demand without compromising quality. Additionally, the machine’s adaptability to various product types is crucial. Some VFFS machine manufacturers offer modular designs that allow operators to switch between different products and packaging materials with minimal downtime.

Another important consideration is precision. Vertical packaging machines should provide accurate filling and sealing to maintain product integrity and customer satisfaction. Features such as automatic bag length adjustment, servo-driven filling systems, and integrated weighing mechanisms enhance precision and reduce wastage. Moreover, safety and compliance features, such as emergency stops, safety guards, and hygiene-friendly materials, ensure that operations meet regulatory standards. Evaluating these features in detail can help businesses identify vertical packaging machines that not only meet current needs but also support future scalability.

Evaluating VFFS Machine Manufacturers

Choosing the right VFFS machine manufacturer is just as important as selecting the machine itself. Reputable manufacturers bring years of experience, technical expertise, and reliable customer support. When evaluating manufacturers, consider factors such as their track record, client testimonials, and global presence. Established VFFS machine manufacturers often provide comprehensive after-sales services, including installation, training, maintenance, and spare parts supply.

It is also beneficial to assess the manufacturer’s innovation capabilities. Leading manufacturers continuously invest in research and development to introduce machines with enhanced features, energy efficiency, and automation technologies. These innovations can give businesses a competitive edge by reducing operational costs and improving packaging quality. Furthermore, manufacturers who understand industry-specific requirements can offer tailored solutions that optimize performance and minimize downtime. Engaging directly with VFFS machine manufacturers and requesting demonstrations or case studies can provide valuable insights into machine reliability and manufacturer support.

Considerations for Machine Maintenance and Longevity

A vertical packaging machine is a significant investment, so considering maintenance requirements and long-term durability is essential. Machines with easy access to critical components, self-diagnostic systems, and clear operational manuals reduce downtime and ensure smooth production. Regular maintenance, including lubrication, cleaning, and component replacement, extends the machine’s lifespan and maintains consistent performance.

Additionally, energy efficiency is an important factor in modern production environments. Machines designed with energy-saving features not only reduce operational costs but also align with sustainability goals. Choosing a vertical packaging machine from manufacturers known for quality engineering, robust construction, and durable materials ensures that your investment provides reliable service over many years. Businesses should also inquire about warranty terms and availability of spare parts, as these factors impact long-term operational efficiency.

Making the Final Decision: Balancing Cost, Quality, and Efficiency

While price is often a deciding factor, it should not be the sole consideration when selecting a vertical packaging machine. Balancing cost, quality, and efficiency is critical for achieving maximum return on investment. A slightly higher upfront investment in a reliable, high-speed machine can result in significant savings over time by reducing labor costs, minimizing material waste, and avoiding frequent repairs.

Before finalizing a purchase, businesses should compare multiple VFFS machine manufacturers, evaluate their machine specifications, and consider customer support and warranty offerings. Additionally, seeking feedback from other companies in your industry can provide practical insights into machine performance and reliability. By taking a holistic approach to the selection process, businesses can secure a vertical packaging machine that not only meets immediate production needs but also supports long-term growth and operational excellence.

Conclusion

Choosing the best vertical packaging machine from top VFFS machine manufacturers requires careful research, detailed evaluation of machine features, and consideration of manufacturer reliability. From understanding the operational benefits of vertical machines to assessing key features, manufacturer credibility, and maintenance requirements, each step is crucial for making an informed decision. By balancing cost, quality, and efficiency, businesses can invest in a vertical packaging machine that enhances productivity, ensures consistent product quality, and delivers long-term value. Selecting the right VFFS machine ultimately positions your business for success in an increasingly competitive market, providing the tools needed to streamline operations and achieve sustainable growth.