Recently, the SUBLISTAR DTF-6004 Star IV DTF Printer underwent a rigorous evaluation by Keypoint Intelligence, a globally recognized authority in digital imaging testing. The results offer a detailed look into what this machine can actually do in a production environment, moving beyond the spec sheet to real-world performance.

The comprehensive report highlights several standout features, particularly regarding color gamut and ink efficiency. For print shops aiming to deliver premium results while managing overhead, understanding these test results is essential. This article breaks down the key findings from the Keypoint Intelligence report to help you decide if the Star IV is the right addition to your production line.

A Closer Look at the Hardware

The SUBLISTAR DTF-6004 Star IV DTF printer is a 600mm width printer designed for high-volume production. Under the hood, the tested configuration features four Epson i3200 printheads. While many standard DTF printers stick to a basic CMYK+White setup, the Star IV takes a more advanced approach to color reproduction.

The tested unit was equipped with an expanded ink set that included Light inks (Light Cyan, Light Magenta, Light Black, Light Light Black) and Spot colors (Red, Green, Blue, Orange). This configuration is specifically engineered to maximize image quality and smooth out gradients, which is often a pain point in standard DTF printing.

Beyond the print engine, the system includes the SUBLISTAR S10i powder shaker and a curing unit designed with energy efficiency in mind. The curing station features a design that minimizes heat escape, reducing the energy required to maintain consistent temperatures—a small detail that adds up to significant savings over a year of production.

Unmatched Color Performance

One of the most significant findings in the Keypoint Intelligence report was the device’s color capability. When printing on white t-shirts, the Star IV DTF printer achieved what the testers described as the “largest color gamut to date.”

Gamut and Accuracy

The expanded ink set allows the printer to hit colors that standard CMYK configurations simply cannot reach. On white t-shirts, the machine recorded a color gamut volume of 338,491 in High Quality mode. This resulted in vibrant vector graphics and realistic memory colors.

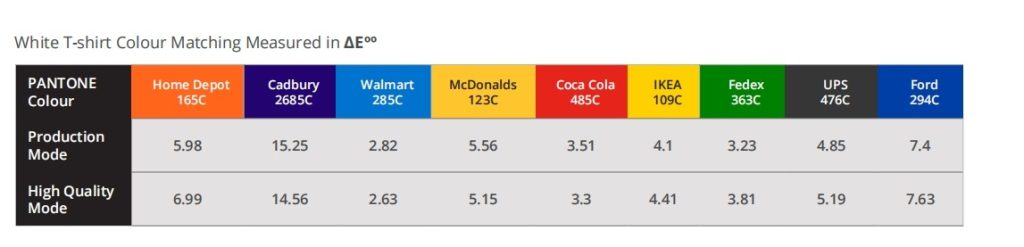

The report noted that the output avoided the graininess often seen in DTF prints. Instead, the results showed smooth skin tones and crisp fine details. In terms of color matching accuracy, the device performed exceptionally well. The average Delta E00 (a metric used to measure the distance between two colors) was just 5.86 on white shirts, which is considered well above average for this category.

Handling Black Garments

Printing on black substrates presents a unique challenge for any DTF printer due to the reliance on a white underbase. The Star IV maintained above-average performance here as well. While the gamut size was naturally smaller than on white shirts (standard for the technology), the vector reproduction remained excellent with rich solids and smooth gradations.

Efficiency and Ink Consumption

For production managers, the cost of ink is a daily calculation. The Keypoint Intelligence testing revealed that the SUBLISTAR 6004 Star IV DTF printer is surprisingly frugal.

Ink consumption on standard test targets was among the lowest the testers had seen. Perhaps more importantly, the machine’s maintenance routines are designed to minimize waste. The printer conducts an automatic “weak” strength cleaning cycle every six hours to prevent nozzle blockages.

According to the data, this routine consumes only about 7.24ml of ink per day. This automated efficiency means operators spend less time manually cleaning heads and more time printing, while the shop wastes less expensive ink on maintenance cycles.

Durability and Washability

A beautiful print is useless if it peels off after a few washes. To test durability, Keypoint Intelligence subjected printed samples to a rigorous cycle of washing and drying.

The testing protocol involved 20 wash/dry cycles at 30ºC using standard detergent. The results showed that the Star IV prints are built to last.

- Color Stability: There was only minor degradation in quality after 20 cycles.

- Cracking and Peeling: Both white and black t-shirt samples were classified as perfectly suitable for external use after the full wash test.

- Stretch: The prints maintained good elasticity, showing no major degradation even when subjected to stretch tests after multiple washes.

The report also highlights a “Transparent Ink” option offered by SUBLISTAR. This ink can replace the Light or Spot color channels and is marketed to improve washability results for fine detail work, such as tagless neck labels or delicate wash instructions.

Speed and Workflow

While quality is paramount, speed determines throughput. The Star IV is rated for speeds up to 12m²/hr in 4-pass mode. During the testing in Production Mode (6 pass, 720 x 1800dpi), the device clocked in at approximately 7.09m²/hr.

For shops requiring the absolute highest definition, the High Quality mode (12 pass, 720 x 2400dpi) runs at roughly 3.54m²/hr. While these aren’t the fastest raw speeds on the market, the trade-off is the exceptional definition and color range provided by the 12-color setup.

To help manage workflow, SUBLISTAR includes their MPM (Multi-Printer Manager) software. This allows a single computer to control multiple machines simultaneously, enabling a single operator to manage a printer farm efficiently.

Conclusion

The Keypoint Intelligence report paints a clear picture of the SUBLISTAR DTF-6004 Star IV DTF printer: it is a machine built for quality. By utilizing an expanded ink set and high-precision printheads, it achieves a level of color fidelity and smoothness that stands out in the crowded DTF market.

While it may not be the single fastest machine available, its efficiency in ink usage and robust build quality make it a compelling option for businesses that refuse to compromise on output quality. The certification confirms that for premium apparel decoration, the Star IV is a serious contender.

If you are looking to upgrade your production capabilities with a certified, high-performance machine, it is worth taking a deeper look at the data.