Introduction

A high-quality mold for injection molding machine is essential to manufacturing success. Whether you’re creating a simple plastic part or a complex, high-precision component, the mold determines the accuracy, efficiency, and durability of every production run.

At RapidMolding.com, businesses can count on expertly crafted molds designed to fit any injection molding machine. With over three decades of experience and millions of parts delivered, RapidMolding.com delivers the perfect mold to match your part design, material requirements, and production goals.

What is a Mold for Injection Molding Machine?

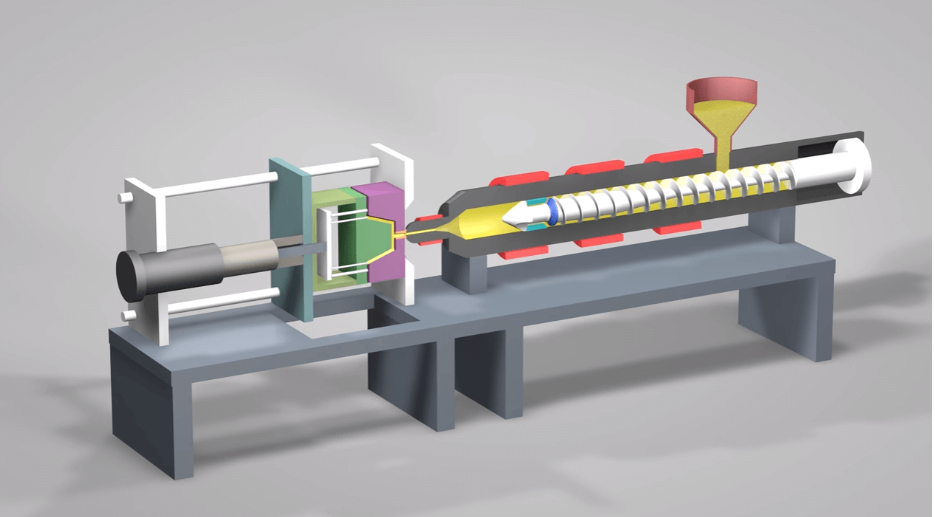

A mold for injection molding machine is a custom-engineered tool made from steel or aluminum. It’s mounted inside an injection molding machine, where molten plastic is injected under high pressure, forming the desired part shape. The mold consists of two halves—core and cavity—that come together to form the part’s geometry.

The precision and quality of the mold are critical, as they influence the final product’s detail, consistency, and strength.

Importance of Choosing the Right Mold

Selecting the right mold is not just about shape—it’s about performance, cost-efficiency, and long-term production success.

Key Considerations:

- ✅ Material Compatibility – Mold must withstand the pressure and temperature of the chosen plastic resin

- ✅ Mold Durability – Hardened steel for high volume; aluminum for prototyping

- ✅ Cycle Efficiency – Optimized cooling and ejection systems for fast production

- ✅ Tolerances – Tight control for critical dimensions and functionality

Mold Types Offered by RapidMolding.com

RapidMolding.com provides a full range of mold solutions tailored to your production needs, machine size, and part complexity.

1. Prototype Molds

- Cost-effective for testing designs

- Ideal for low-volume production

- Lead time: 2–4 weeks

- Mold life: up to 10,000 shots

2. Bridge Molds

- Perfect for mid-volume runs

- Lead time: 3–6 weeks

- Mold life: up to 300,000 shots

- Affordable alternative to full-scale production molds

3. Production Molds

- High-durability molds for millions of cycles

- Fully hardened steel with advanced cooling

- Lead time: 4–8 weeks

- Designed for 24/7 manufacturing environments

Custom Mold Design Services

Every project at RapidMolding.com begins with an in-depth design process to ensure mold compatibility with your injection molding machine.

Services Include:

- 🛠 CAD Design & Simulation – 3D modeling, mold flow analysis

- 🧑💻 Design for Manufacturability (DFM) – Ensures efficient part ejection and minimal defects

- 🧪 Material Selection Support – Choose the best plastic and mold materials for durability and cost

- 🔧 Precision Machining – CNC, EDM, and surface finishing

Compatibility with All Injection Molding Machines

RapidMolding.com designs molds compatible with various machine types and sizes—from small desktop machines to large industrial systems.

Machine Compatibility:

- Horizontal and vertical molding machines

- Hydraulic, electric, and hybrid systems

- Custom mold base sizes and mounting configurations

- Multi-cavity and family mold options for efficiency

Mold Maintenance and Ownership

Owning a mold is an investment. RapidMolding.com offers services to extend mold life and ensure readiness for repeat production.

- 🔍 Inspection & Testing – Every mold undergoes quality checks before shipment

- 🧰 Maintenance Plans – Cleaning, repair, and refurbishing available

- 📦 Free Storage – Molds stored securely for 12 months at no cost

- ✅ Full Ownership – Customers own the mold for bridge and production tooling

Industry Applications

Reliable molds for injection molding machines are critical across sectors.

- 🚗 Automotive – Engine components, clips, housings

- 🏥 Medical – Precision tools, device housings

- 🛠 Industrial – Gears, knobs, machine parts

- 📱 Consumer Electronics – Enclosures, connectors

- 🛒 Retail & Packaging – Caps, containers, closures

Why Choose RapidMolding.com?

- ✔ 30+ Years of Experience in mold making

- ✔ Custom Solutions for any injection molding machine

- ✔ Fast Turnaround Times to meet tight deadlines

- ✔ Transparent Pricing – No surprises

- ✔ Global Shipping and on-time delivery

Conclusion

A durable, precisely engineered mold for injection molding machine is the key to successful plastic part production. With RapidMolding.com, you get expert support, fast delivery, and molds designed for long-term value.

Get a Quote Today

Visit RapidMolding.com to request your custom mold and discover how the right tool can elevate your manufacturing success.