prototypes within a few days. It’s all about compressing the design–build–test cycle so teams can validate ideas and move forward quickly.

This article explains what “quick turn” really means, what affects turnaround time, how to prepare your files, and how to choose the right partner for your quick Turn PCB Prototyping and assembly needs.

What Counts as “Quick Turn” Today

In the PCB industry, “quick turn” typically means you can get your prototype boards in 24 to 72 hours—sometimes even faster for simple designs. By comparison, standard PCB production often takes 2 to 3 weeks.

Quick turn is part of the broader trend toward rapid PCB prototyping, where design revisions happen fast and frequently. Engineers use it to shorten product validation cycles, reduce risk, and speed up launch schedules. The faster you can get your first working boards, the sooner you can test, iterate, and build better hardware.

The Four Levers That Decide Turnaround Time

Even the best quick-turn services depend on several factors that affect the clock. Here are four main levers to keep in mind:

- Design Complexity

The more layers, blind/buried vias, impedance control, or fine-pitch BGAs you have, the longer it takes. Simple 2–4-layer boards can often ship in 1–2 days, while 8–12-layer HDI designs may take longer. Keep your prototype stack-up simple whenever possible. - Material and Process Availability

Using standard FR-4, copper weights, and common solder mask colors speeds things up. Special materials like Rogers or Isola laminates, thick copper, or uncommon finishes (such as ENEPIG) often add extra hours or days. - File Quality and DFM Readiness

Incomplete or inconsistent Gerbers can delay engineering review. Always double-check that your drill files, solder mask openings, silkscreen, and layer names are aligned. A thorough DFM (Design for Manufacturability) review saves time and reduces communication cycles. - Order Timing and Cut-Off Windows

Most manufacturers have daily cut-off times for quick-turn orders. Submitting your files and payment before the deadline ensures your boards start production immediately.

A well-prepared design and complete documentation can make the difference between a 2-day and a 5-day delivery.

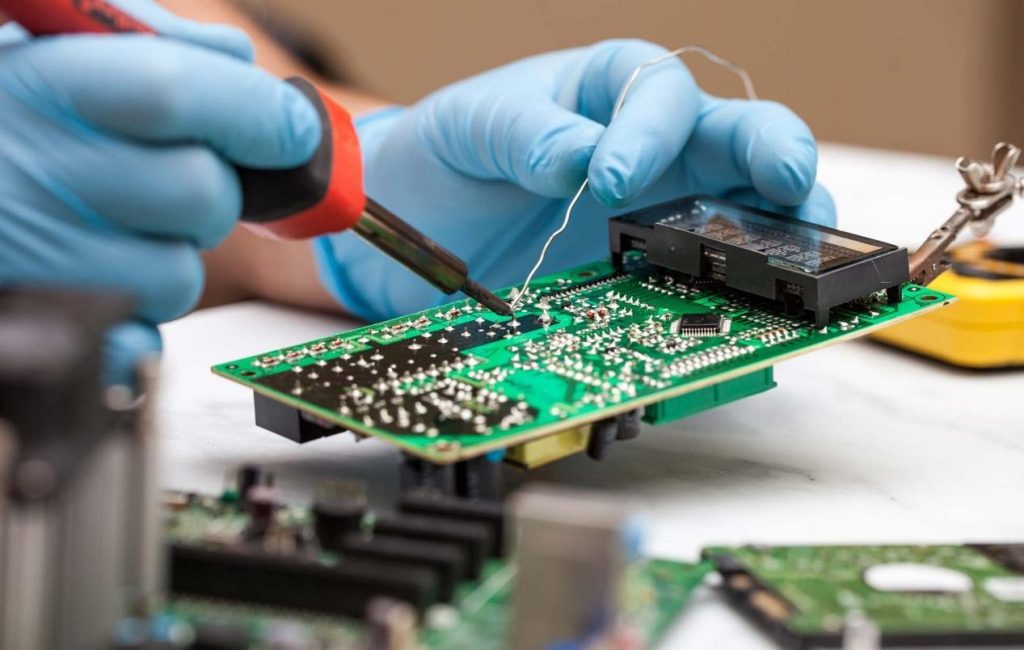

From Bare Boards to Rapid Prototyping PCB Assembly

Modern engineers rarely stop at bare boards. Many projects now include rapid prototyping PCB assembly, where the same supplier handles fabrication, parts sourcing, and assembly under one roof. This turnkey approach eliminates multiple handoffs and logistics delays.

With turnkey service, procurement, and assembly run alongside fabrication. Some providers deliver assembled prototypes in 2–3 days. Use common components, approve alternates in your BOM, and mark DNP (Do Not Place) parts to achieve the fastest results.

Design for testability also helps accelerate validation. Add accessible test points, consider small panelized boards with V-cuts or mouse bites, and, if needed, request quick ICT or functional testing. That ensures your prototype is not only built fast but also ready to power up and perform.

Your 24–72h File Prep Checklist

Speed starts with clean data. Here’s what to prepare before you upload your order:

- Gerber Files: Verify consistent layer naming, alignment, and solder mask openings. Include board outline and tooling holes.

- Drill File: Provide separate plated and non-plated drills, plus a clear drill chart.

- Stack-Up Info: Specify the number of layers and any impedance requirements.

- Bill of Materials (BOM): List part numbers, quantities, and alternates if possible.

- Pick-and-Place (XY) File: Include coordinates, rotations, and DNP notes.

- Engineering Notes: Add requests for surface finish, panelization, or test needs.

A complete, readable package ensures engineering review happens once—not twice—and your boards move straight to production.

Cost vs. Speed: Practical Ways to Save

Quick turn doesn’t have to be costly. Save by using standard materials, avoiding exotic specs, and not over-engineering prototypes.

- Avoid over-specifying in prototypes — skip gold fingers, thick copper, or microvias unless required.

- Group your test boards into a small batch order to save on setup costs.

- Ask your supplier about combined fabrication + assembly discounts.

Small design changes or the use of standard colors can reduce both time and cost. Quick turn is about optimization, not shortcuts.

FAQ

Where can I get a quick turn PCB prototype designed?

Look for a manufacturer that provides complete engineering support, DFM review, and turnkey services. Uploading your Gerber, BOM, and pick-and-place files to a full-service platform ensures your prototype is built and assembled without unnecessary delays.

How fast can the assembly ship?

If components are in stock and your BOM is substitution-friendly, many suppliers can ship assembled prototypes within 2–3 business days after fabrication.

Do I need HDI for my prototype?

Not always. Unless your design requires high-density interconnects or fine-pitch BGAs, start with standard through-hole vias. Simpler builds mean faster and cheaper prototypes.

Conclusion

Fast, reliable prototyping helps you test, learn, and move to production with confidence. The secret to success is preparation: clean files, practical design rules, and a responsive manufacturing partner. With proper planning, your idea can go from schematic to working hardware in just a few days.

To learn more about professional one-stop solutions — from PCB fabrication to full assembly — visit FastTurn PCB. Their integrated quick turn services help engineers build, test, and launch faster than ever.