1.1 The Evolution of SLA and DLP Technologies

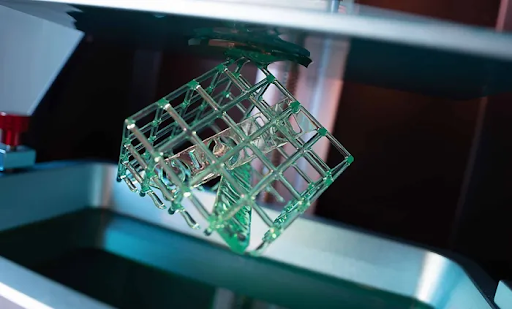

Stereolithography (SLA) and Digital Light Processing (DLP) have matured into highly efficient, production-ready additive manufacturing (AM) technologies. Unlike traditional polymer AM methods—such as fused deposition modeling (FDM) or selective laser sintering (SLS)—SLA and DLP systems utilize photopolymerization to achieve high-precision, isotropic, and mechanically robust parts. The introduction of high-performance resins 3D printing has further enhanced their capabilities, allowing these systems to produce parts comparable to thermoplastics like ABS, polyamide (PA12), polypropylene (PP), and ULTEM.

DLP and SLA offer several key advantages that make them particularly well-suited for industrial and commercial applications:

- High Resolution & Surface Quality: Layer resolutions as fine as 25 µm allow for intricate geometries and smooth surfaces with minimal post-processing.

- Fast Print Speeds: DLP’s area-wide exposure mechanism enables higher throughput than vector-based methods like laser sintering.

- Isotropic Properties: Unlike FDM, which suffers from anisotropic mechanical properties due to layer adhesion inconsistencies, SLA/DLP parts exhibit uniform strength and structural integrity in all directions.

- Rapid Material Swapping: Unlike powder-bed fusion (PBF) technologies that require complex material changeovers and handling protocols, SLA/DLP resins can be switched within minutes.

- Diverse Material Library: The new generation of photopolymer resins includes high-performance thermoplastic analogs, elastomers, biocompatible materials, and specialty formulations such as ceramic-filled composites.

1.2 Comparing SLA/DLP to Competing AM Technologies

SLA/DLP’s unique advantages position it as a strong competitor to other AM technologies, particularly for low- to mid-volume production runs. Table 1 summarizes key performance differences between SLA/DLP, FDM, and PBF systems:

| Feature | SLA/DLP | FDM | SLS/PBF |

| Surface Finish | Injection mold-like | Layered, rough | Powdery, grainy |

| Print Speed | High (DLP: area-wide) | Moderate (vector-based) | Low (powder recoating required) |

| Material Changeover | Minutes (resin swap) | Minutes (filament change) | Hours (powder sieving, cleaning) |

| Mechanical Isotropy | High (cDLM capable) | Low (anisotropic) | High |

| Support Removal | Easy (solvent/washable) | Hard (mechanical removal) | Easy (powder brushing) |

| Part Density | High | Medium | High |

While PBF systems (such as SLS and multi-jet fusion) remain dominant in large-scale production of engineering polymers, they require complex powder-handling processes and significant post-processing. SLA/DLP eliminates these challenges by offering liquid resins with straightforward curing and post-processing steps, making it highly attractive for businesses needing agile, on-demand manufacturing capabilities.

1.3 Overcoming Historical Stigmas of Resin-Based Printing

For decades, SLA/DLP resins were considered brittle, unstable, and unsuitable for long-term applications. However, recent advancements have addressed these limitations, introducing new material formulations that rival traditional thermoplastics in both mechanical and chemical performance. Modern SLA/DLP resins now offer:

- Stable Mechanical Properties: No significant degradation over time, even under mechanical loads.

- High Toughness & Impact Resistance: Certain formulations now achieve elongation-at-break values exceeding 100%, making them suitable for dynamic applications.

- High-Temperature Performance: Materials with HDTs exceeding 300°C enable applications in aerospace, automotive, and high-temperature tooling.

- Highly Ceramic-Filled Composites: These materials provide superior wear resistance, dimensional stability, and surface quality.

- Enhanced Burnout Properties: High-wax-content resins now support direct investment casting for jewelry, dental, and industrial applications.

These improvements dismantle the long-standing perception that SLA/DLP printing is limited to brittle, prototype-grade parts, solidifying its role in end-use manufacturing.

2. Breaking the Stigma: The New Generation of High-Performance Resins

One of the primary arguments in favor of SLA/DLP technologies is the exceptional material versatility they now offer. Unlike powder-based or filament-based systems, where material properties are constrained by powder flowability or extrusion limitations, liquid resin formulations provide nearly unlimited potential for chemistry-driven enhancements.

2.1 Key Advancements in SLA/DLP Resin Chemistry

The development of high-performance photopolymer resins has been driven by three major innovations:

- Hybrid Multi-Cure Systems: Many modern SLA/DLP resins now incorporate dual or multi-cure chemistries, allowing secondary thermal post-curing to improve strength, impact resistance, and thermal performance.

- Nanocomposite & Ceramic Fillers: By incorporating nano-sized ceramic or glass fillers, resin-based parts can achieve wear resistance and thermal stability comparable to traditional thermoplastics.

- Elastomeric Crosslinking: The introduction of flexible resins with controlled crosslinking enables the production of soft, durable parts that function similarly to TPUs and silicones.

These breakthroughs allow SLA/DLP printing to enter new markets, competing directly with injection-molded thermoplastics in terms of performance, reliability, and longevity.

2.2 Expanding the Application Scope of SLA/DLP Materials

With these material advancements, SLA/DLP has transitioned from being a purely prototyping tool to a viable manufacturing solution for industries requiring high-performance components.

2.2.1 Aerospace & Automotive Applications

- High-Temperature Resins: New formulations with HDTs above 200°C enable parts to withstand extreme thermal cycling.

- Flame-Retardant & FST-Compliant Resins: Photopolymer materials meeting UL94 V-0 and Airbus AITM flame, smoke, and toxicity (FST) standards are now available, making SLA/DLP suitable for aircraft and automotive interiors.

2.2.2 Medical & Biocompatible Applications

- ISO 10993-5 & -10 Certified Resins: Biocompatible photopolymers now support the production of patient-specific medical devices, including surgical guides and prosthetic components.

- Soft Tissue Simulation Materials: Silicone-like elastomers allow for high-resolution anatomical models for preoperative planning.

2.2.3 Industrial Tooling & Manufacturing

- Wear-Resistant Ceramics: High-strength ceramic-filled resins are now used in mold masters, jigs, and fixtures.

- Injection Mold Prototyping: SLA/DLP resins with high compressive strength enable the rapid fabrication of short-run injection molds.

These applications demonstrate that SLA/DLP technologies have moved beyond their initial niche as a rapid prototyping tool and are now enabling full-scale production in diverse industries.

3. The Business Case for SLA/DLP in Low-Volume Manufacturing

With the rise of Industry 4.0 and on-demand manufacturing, businesses are increasingly looking for agile production solutions that allow for rapid iteration and material flexibility. SLA/DLP’s ability to produce high-performance parts quickly, while maintaining low material changeover times, makes it an ideal choice for low-to-mid-volume production.

3.1 Cost Efficiency Compared to Powder Bed & Filament Systems

In traditional AM workflows, material handling and post-processing introduce significant cost factors. SLA/DLP eliminates many of these inefficiencies through:

- Lower Material Waste: Unlike PBF, which requires excess powder to be sieved and reused, SLA/DLP resin is used efficiently with minimal material loss.

- Faster Production Speeds: DLP’s area-wide curing mechanism significantly reduces print time compared to FDM’s or laser-based scanning.

- Simplified Post-Processing: SLA/DLP prints require only washing and UV curing, avoiding the need for extensive depowdering or mechanical support removal.

3.2 Rapid Material Swapping & Multi-Material Flexibility

One of the strongest advantages of SLA/DLP is its ability to switch between different materials quickly. Unlike filament-based or powder-based systems that require thorough purging or sieving processes, SLA/DLP resins can be swapped in minutes, enabling manufacturers to use different materials for different applications within the same workflow.

These factors establish SLA/DLP as a highly versatile and cost-effective technology for small-batch and customized manufacturing needs.

4. Conclusion: SLA/DLP as a Viable Alternative to Injection Molding

With EnvisionTEC’s advanced resins, SLA/DLP printing has moved beyond prototyping into full-scale production. These materials offer a combination of mechanical performance, thermal resistance, and flexibility that rival traditional manufacturing processes, making SLA/DLP the most versatile AM technology available today.

For more information, visit RapidMade.