Buying your first laser cutting machine can feel like stepping into a maze. Between different machine types, power ratings, and features, it’s easy to feel unsure where to start. This guide is designed to give beginners a practical roadmap, explaining what to look for, how to match a machine to your needs, and how to avoid costly mistakes. By the end, you’ll have a clear understanding of laser cutting options and know what to prioritize.

Step 1: Get Familiar with Laser Cutter Types

Not all laser cutters are built the same, and knowing the differences is crucial:

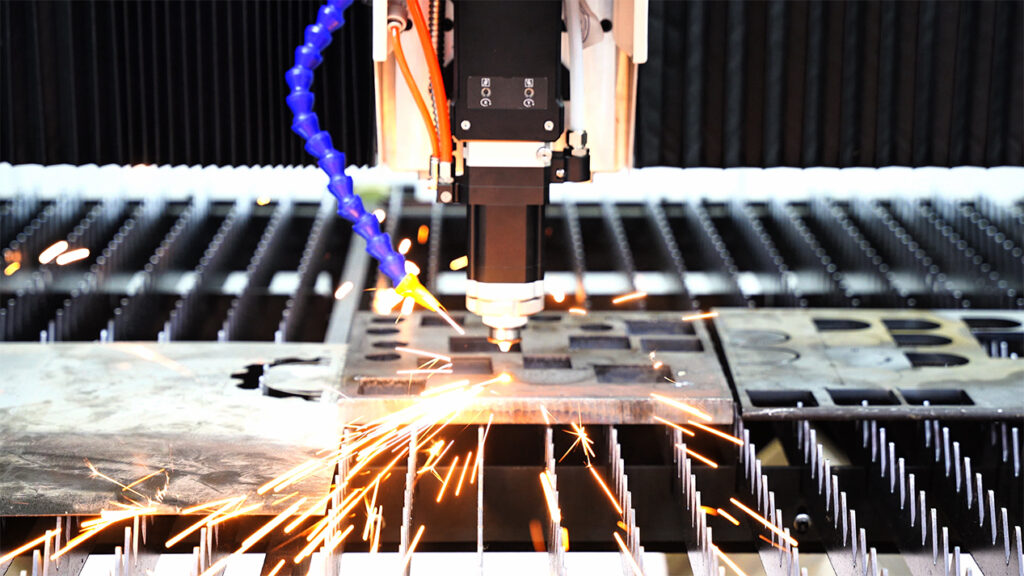

Fiber Laser Cutters

These excel at cutting metal, offering high speed, precision, and long-term reliability. Minimal maintenance requirements make them ideal for industrial workshops or small factories aiming for efficiency.

CO2 Laser Cutters

Perfect for materials like wood, acrylic, or plastics. They can handle metals but are generally slower and less efficient than fiber lasers.

Material and Thickness Guidelines

- Carbon steel: 0.5–25 mm

- Stainless steel: 0.5–20 mm

- Aluminum alloys: 0.5–12 mm

Choosing the correct laser type depends heavily on the materials you plan to process. Selecting the wrong type can slow production and reduce cut quality.

Step 2: Understand How Laser Power Impacts Performance

Laser power isn’t just a number—it affects how fast you can cut, the thickness you can handle, and overall efficiency. Consider these ranges:

- 1–3 kW fiber lasers: Suitable for light workloads or smaller projects

- 4–6 kW and above: Necessary for high-volume or heavy-duty industrial applications

Matching your machine’s power to your production needs ensures smooth cuts without paying for unnecessary capacity.

Step 3: Clarify Your Cutting Needs

Sheet vs. Tube Cutting

Some laser systems can process both sheets and tubes, while others focus on a single type. If your operations require both, a combined system can save space and investment costs.

Automation Options

Features like automatic loading, CNC controls, or multi-axis cutting can dramatically increase productivity. If your goal is consistent output with minimal hands-on operation, these options are worth considering.

Step 4: Factor in Total Costs and ROI

The initial price tag is only part of the investment. Operating costs matter too:

- Power consumption

- Gas usage (oxygen, nitrogen)

- Replacement parts and consumables such as lenses and nozzles

Machines like Glorystar fiber laser cutters are designed to reduce these ongoing expenses while delivering reliable performance, giving you a faster return on investment and less downtime.

Step 5: Tips for New Users

Getting Started

Modern laser cutters are compatible with popular design software such as CAD or CorelDRAW. Beginners should start with thinner materials and simpler designs to learn optimal settings for speed, focus, and power.

Troubleshooting Common Problems

- Cuts look rough → Recheck speed and focus

- Machine won’t start → Inspect the power supply and laser module

- Software errors → Update or re-import your design files

Maintenance Advice

Cleaning lenses, checking gas lines, and lubricating moving parts are essential. Glorystar machines are built for simple maintenance, making them beginner-friendly without sacrificing performance.

Step 6: Safety and Workspace Organization

- Always wear protective gear and use appropriate shields

- Ensure proper ventilation to manage fumes and dust

- Keep your workspace tidy to prevent accidents and optimize workflow

An organized, safe environment not only protects operators but also supports consistent, high-quality production.

Step 7: Choose a Reliable Manufacturer

A strong manufacturer ensures support long after purchase. Look for:

- Warranty coverage and easy access to spare parts

- Technical support and training resources

Glorystar offers fiber laser cutters that combine worldwide support with intuitive operation, allowing beginners to work efficiently and confidently.

Step 8: Strategies to Increase Efficiency

- Adjust cutting settings to balance speed with precision

- Preload frequently used designs to save setup time

- Plan batch processing for consistent quality and time savings

Even small workflow optimizations can have a major impact on overall productivity, especially for those new to laser cutting.

Conclusion

Before investing in a laser cutting machine, it’s important to understand your material requirements, power needs, machine type, operating costs, and safety considerations. By following this guide, beginners can make informed decisions and choose a machine that aligns with their production goals. Glorystar fiber laser cutters stand out for their combination of reliability, ease of use, and professional-quality results, ensuring a fast return on investment and a smooth start for first-time users.

With these insights, you’re now better equipped to select a laser cutting machine that fits both your projects and long-term goals.