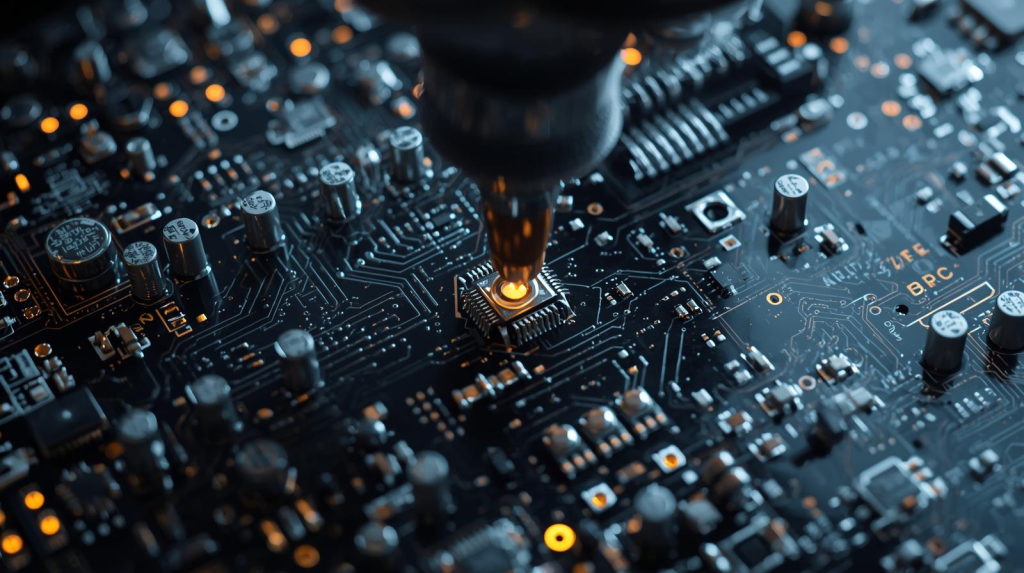

When it comes to developing new electronic devices, prototyping plays a pivotal role. Quick turn prototype PCB assembly is a crucial step that accelerates product development by allowing engineers to test their designs with real-world circuits before mass production. FastTurn PCB is one of the leading providers in the industry, offering fast and efficient solutions for PCB assembly. In this article, we’ll explore everything you need to know about quick turn prototype PCB assembly, including the process, benefits, and how FastTurn PCB can help you bring your projects to life faster. Whether you’re a startup or an established company, the right prototype assembly service can be the difference between success and delay.

What is Quick Turn Prototype PCB Assembly?

Quick turn prototype PCB assembly refers to the rapid production of printed circuit boards (PCBs) used for testing and validation. Unlike traditional PCB manufacturing, where the timeline may span several weeks, quick turn services are designed to deliver prototypes in a fraction of the time—typically in as little as 24 to 48 hours. This speed is essential for companies that need to test their products before committing to large-scale production.

Benefits of Quick Turn Prototype PCB Assembly

- Faster Time to Market

In today’s fast-paced tech industry, speed is everything. With quick turn PCB assembly, companies can accelerate their product development cycle and reduce the time it takes to get to market. - Lower Risk of Design Errors

Testing your design early with quick turn prototypes helps identify issues that may not have been evident in simulations. This leads to better-quality products and fewer costly mistakes. - Cost Efficiency

By using a prototype for testing, manufacturers can avoid costly design errors that could arise during mass production. Quick turn PCB assembly offers a cost-effective way to validate designs before making a significant financial commitment. - Flexibility and Scalability

Quick turn PCB assembly services, like those offered by FastTurn PCB, can handle different designs and complexity levels, making them perfect for a variety of projects. Whether you need one board or multiple prototypes, the flexibility is key.

Why Choose FastTurn PCB for Prototype Assembly?

FastTurn PCB has earned its reputation as a leading provider of quick turn prototype PCB assembly. Here’s why they stand out:

- Rapid Turnaround Times: FastTurn PCB specializes in quick turn services, providing fast and reliable delivery even for complex prototypes.

- Quality and Reliability: Their state-of-the-art manufacturing processes ensure that each prototype meets the highest quality standards, reducing the chances of failure during testing.

- Customization: FastTurn PCB offers customized solutions based on your specific needs, from design layout to component selection, ensuring that each project gets the attention it deserves.

- Experienced Team: Their team of professionals brings decades of experience in the PCB industry, ensuring expert handling of your prototype assemblies.

How Quick Turn Prototype PCB Assembly Works

The process for quick turn prototype PCB assembly typically involves the following steps:

- Design Submission:

You submit your PCB design files to FastTurn PCB, including schematics, layout files, and component specifications. It’s important to ensure that the design files are accurate to avoid errors later in the process. - Component Sourcing:

FastTurn PCB sources the necessary components for your prototype, ensuring availability and compatibility with your design. - Assembly:

The PCB is assembled by placing components on the board using automated or manual assembly techniques, depending on the complexity of the design. - Testing and Validation:

After assembly, the prototype is tested to ensure that it works as expected. This testing phase allows you to catch any issues before full-scale production. - Delivery:

Once the testing is complete and the prototype is validated, it’s delivered to your location, often within a few days.

Tips for Choosing the Right Quick Turn Prototype PCB Assembly Service

Choosing the right service for quick turn prototype PCB assembly can make all the difference. Here are a few tips:

- Assess Turnaround Time:

Ensure that the service can meet your project deadlines. If time is critical, companies like FastTurn PCB offer expedited services that can help you meet tight timelines. - Check Quality Standards:

Quality is just as important as speed. Choose a provider that uses high-quality materials and offers rigorous testing procedures. - Consider Customization:

Not all PCB designs are the same. If your project requires specific features or components, ensure that the provider can accommodate custom specifications. - Experience Matters:

Look for a provider with experience in quick turn prototype PCB assembly. Companies like FastTurn PCB have a proven track record in delivering high-quality prototypes quickly.

Common Mistakes in Prototype PCB Assembly

While using quick turn prototype PCB assembly can save you time, there are common mistakes that can hinder your success:

- Poor Design Files:

Inaccurate or incomplete design files can delay the assembly process or result in defects. Make sure your files are thoroughly checked before submission. - Underestimating Testing Requirements:

Testing is crucial for ensuring the functionality of your prototype. Skipping or rushing through this step can result in costly mistakes during later production phases. - Ignoring Manufacturer Capabilities:

Not every assembly service is equipped to handle all types of PCBs. Always check the capabilities of your chosen provider to ensure they can handle your specific requirements.

How FastTurn PCB Can Help

If you’re looking for a quick turn prototype PCB assembly solution, FastTurn PCB can help. With years of experience in the industry, they provide fast and reliable services that meet your deadlines without compromising on quality. Whether you’re working on a new product prototype or need to test a new PCB design, FastTurn PCB offers the flexibility, speed, and expertise to help you succeed.

Conclusion

In conclusion, quick turn prototype PCB assembly is an essential service for any company looking to expedite its product development process. FastTurn PCB stands out in the industry, providing high-quality, fast, and customizable solutions for all your prototype needs. By choosing the right service, you can reduce time-to-market, mitigate risks, and improve product quality, ensuring a smoother path from concept to production. If you’re ready to take your PCB designs to the next level, FastTurn PCB is the trusted partner you need.

FAQ Section

1. What is quick turn prototype PCB assembly?

Quick turn prototype PCB assembly is the process of rapidly producing a PCB prototype for testing and validation, with fast turnaround times of 24-48 hours.

2. Why should I choose FastTurn PCB for prototype assembly?

FastTurn PCB offers fast turnaround times, high-quality standards, and experienced professionals, making them a reliable choice for your quick turn prototype needs.

3. How long does it take to receive a prototype PCB?

Depending on the complexity of the design, FastTurn PCB can deliver prototypes in as little as 24-48 hours, making them ideal for fast-paced projects.

4. Can FastTurn PCB handle complex designs?

Yes, FastTurn PCB is equipped to handle a wide range of PCB designs, from simple to highly complex configurations.

5. How can I get started with FastTurn PCB?

Getting started is easy! Simply submit your design files to FastTurn PCB, and their team will guide you through the process, ensuring that your prototype is delivered on time and to specifications.