The rise of smart factories has revolutionized how industries operate, and at the heart of this transformation lies advanced sensing technology. Rika Sensor has emerged as a key player in this space, offering innovative solutions that help manufacturers increase efficiency, reduce downtime, and improve product quality. By integrating precision sensors and intelligent systems, Rika Sensor enables factories to collect real-time data and make informed decisions faster than ever before. This technology is not just changing production lines—it is redefining the entire approach to modern manufacturing.

Rika Sensor’s devices are designed with versatility in mind, capable of monitoring a wide range of industrial parameters. From temperature and pressure to motion and vibration, these sensors provide critical insights that drive predictive maintenance and optimize operational workflows. As industries face growing demand for automation and smart solutions, Rika Sensor stands out by providing reliable, scalable, and accurate sensing technologies that ensure production continuity while minimizing waste and costs.

Revolutionizing Factory Automation

Automation is no longer a luxury in manufacturing; it is a necessity. Rika Sensor plays a pivotal role in this revolution by offering sensors that seamlessly integrate with robotic systems, conveyor belts, and automated machinery. These sensors detect subtle changes in operational conditions and feed data into centralized control systems, enabling automated adjustments without human intervention. This not only improves precision but also enhances safety, reducing the risk of machine errors or workplace accidents.

The use of Rika Sensor in factory automation also supports real-time analytics, giving manufacturers the ability to monitor production performance continuously. This data-driven approach allows companies to identify inefficiencies, forecast equipment needs, and implement proactive maintenance strategies. By combining Rika Sensor technology with modern automation software, factories can operate smarter, faster, and more sustainably, paving the way for a new era of intelligent manufacturing.

Enhancing Quality Control

Maintaining consistent product quality is a critical challenge for manufacturers. Rika Sensor contributes significantly to quality control by providing highly accurate measurements of key production parameters. These sensors detect deviations in temperature, pressure, or alignment that could compromise the final product. By capturing precise data at every stage of production, Rika Sensor ensures that defects are identified early, reducing the likelihood of costly recalls or rework.

Moreover, the sensors’ ability to communicate with quality management systems helps streamline inspections and audits. Manufacturers can track trends, monitor compliance, and implement corrective actions swiftly, all while reducing reliance on manual checks. This integration of Rika Sensor technology into quality control processes not only improves product consistency but also strengthens brand reputation and customer satisfaction in increasingly competitive markets.

Enabling Predictive Maintenance

Unplanned equipment downtime is one of the biggest challenges in manufacturing, often leading to lost revenue and production delays. Rika Sensor addresses this problem by enabling predictive maintenance strategies. Sensors continuously monitor machine performance, detecting early signs of wear, vibration anomalies, or overheating. This data allows maintenance teams to intervene before a breakdown occurs, ensuring equipment remains operational and reducing unexpected downtime.

Predictive maintenance powered by Rika Sensor also extends the lifespan of industrial machinery. By identifying potential issues early, manufacturers can schedule timely repairs, avoid unnecessary replacements, and optimize maintenance resources. This proactive approach not only saves costs but also improves operational efficiency, allowing factories to meet higher production targets without compromising equipment reliability or safety.

Integrating IoT and Smart Manufacturing

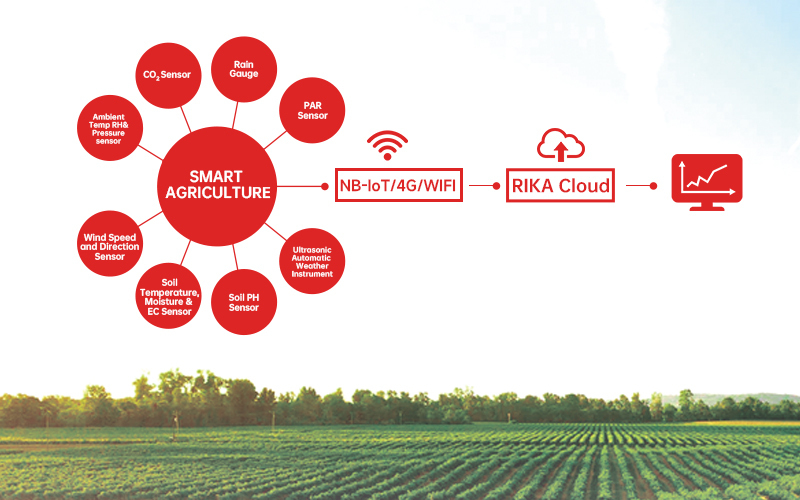

The Industrial Internet of Things (IIoT) is transforming traditional manufacturing into a connected ecosystem, and Rika Sensor is at the forefront of this integration. By linking sensors with cloud-based platforms and advanced analytics tools, factories gain comprehensive insights into operations, supply chains, and production workflows. This connectivity allows for real-time monitoring, remote diagnostics, and intelligent decision-making, giving manufacturers a competitive edge in today’s fast-paced market.

Rika Sensor’s IoT-enabled devices also support scalability and flexibility in smart factories. As production demands shift, these sensors can be reconfigured or expanded to new processes without significant downtime or investment. By combining IoT capabilities with precise sensing technology, Rika Sensor empowers manufacturers to embrace digital transformation, optimize resource utilization, and drive innovation across every stage of production.

Sustainability and Energy Efficiency

Modern manufacturing is increasingly focused on sustainability, and Rika Sensor contributes to this goal by promoting energy efficiency and waste reduction. By providing accurate data on energy consumption, material usage, and operational performance, these sensors help manufacturers identify areas for improvement and implement eco-friendly practices. Real-time monitoring ensures that machines operate within optimal parameters, reducing excess energy use and minimizing environmental impact.

In addition, Rika Sensor enables manufacturers to adopt circular economy practices by tracking product life cycles and predicting maintenance needs. This reduces material waste, extends equipment lifespan, and supports environmentally responsible production. By aligning smart sensor technology with sustainability objectives, Rika Sensor not only enhances operational efficiency but also helps companies meet regulatory requirements and consumer expectations for greener manufacturing.

Future Prospects of Intelligent Manufacturing

The role of Rika Sensor in intelligent manufacturing is only set to grow as industries continue to embrace digitalization. Emerging trends such as AI-driven analytics, autonomous production lines, and advanced robotics will rely heavily on accurate, real-time data from sensors. Rika Sensor’s commitment to innovation ensures that manufacturers have the tools needed to stay ahead in this rapidly evolving landscape. With continuous improvements in sensor accuracy, connectivity, and durability, the future promises smarter, safer, and more efficient manufacturing environments.

As industries pursue greater automation and data-driven decision-making, Rika Sensor will remain a cornerstone of intelligent manufacturing. Its ability to integrate seamlessly with emerging technologies ensures that factories can scale operations, maintain high product quality, and minimize costs. By combining expertise in sensing technology with a forward-looking approach, Rika Sensor is helping shape the factories of tomorrow, driving both economic growth and technological advancement.

Conclusion

Rika Sensor is revolutionizing intelligent manufacturing by offering innovative, reliable, and versatile sensing solutions. From automation and quality control to predictive maintenance and sustainability, these sensors provide the critical data manufacturers need to operate efficiently and competitively. By integrating Rika Sensor technology into production processes, companies can achieve higher precision, reduce downtime, and make informed decisions that enhance productivity and profitability. As smart factories continue to evolve, Rika Sensor remains a key driver of innovation, paving the way for a more connected, efficient, and sustainable future in industrial manufacturing.