Construction sites present some of the most demanding operational environments imaginable. Equipment must endure extreme temperatures, abrasive dust, constant vibrations, and relentless workloads that can quickly overwhelm underpowered or poorly designed machinery. In these challenging conditions, engine failure isn’t just an inconvenience—it translates to costly downtime, missed deadlines, and frustrated crews. The QSK50 Cummins engine emerges as a purpose-built solution designed specifically to thrive where other engines struggle. This powerhouse combines exceptional output capabilities with battle-tested durability, offering construction companies a reliable foundation for their heaviest equipment. With advanced engineering that addresses the unique demands of jobsite operations, from integrated cooling systems to reinforced components, the QSK50 delivers consistent performance when it matters most. This article explores why the QSK50 Cummins has become the preferred choice for construction professionals operating in harsh environments, examining its power delivery, durability features, integration capabilities, and long-term value proposition that keeps projects moving forward regardless of conditions.

Unmatched Power and Performance of the QSK50 Cummins

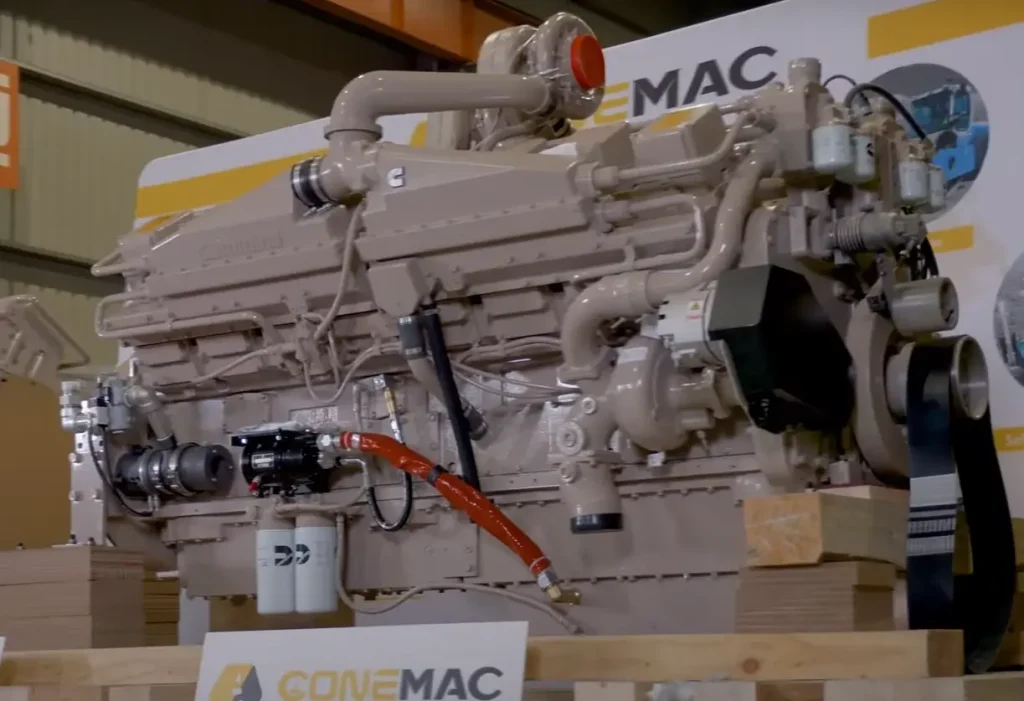

The QSK50 series represents Cummins’ flagship heavy-duty engine line, delivering between 1,400 and 2,500 horsepower with displacement of 50 liters. This turbocharged powerhouse generates massive torque output that enables construction equipment to handle the most demanding tasks without hesitation. Whether powering large excavators moving thousands of cubic yards daily or driving crushers processing dense aggregate materials, the QSK50 maintains consistent performance under sustained heavy loads that would cause lesser engines to falter.

What distinguishes the QSK50 from competing engines in its class is the combination of raw power with intelligent fuel delivery systems that optimize combustion efficiency. The advanced turbocharging technology provides immediate throttle response, eliminating the lag that can slow productivity during critical operations. When compared to engines from other manufacturers offering similar displacement, the QSK50 consistently delivers superior power-to-weight ratios and better fuel consumption figures across varying load conditions.

Construction professionals operating the QSK50 in real-world scenarios report impressive capabilities. One mining operation in Australia documented their QSK50-powered haul trucks maintaining full speed on steep grades while carrying maximum payloads, a task where their previous engines required downshifting and extended cycle times. Another contractor running drilling equipment in the Middle East noted that the engine sustained peak output throughout 12-hour shifts in temperatures exceeding 120°F, completing projects ahead of schedule. These performance characteristics translate directly to increased productivity, allowing construction companies to accomplish more work with fewer machines and shorter project timelines, ultimately improving their competitive position in demanding markets.

Built to Withstand Harsh Construction Conditions

The QSK50 Cummins incorporates reinforced engineering specifically designed to survive the punishing realities of construction environments. Its heavy-duty block construction features thicker cylinder walls and reinforced main bearing caps that absorb the constant vibrations generated by crushing, drilling, and excavation operations. The engine’s advanced filtration systems protect critical components from the abrasive dust and particulates that pervade construction sites, with multi-stage air filters capturing contaminants before they reach combustion chambers. The cooling system utilizes oversized radiators and high-capacity oil coolers that maintain optimal operating temperatures even when ambient conditions soar above 115°F or plunge below freezing.

Field performance in extreme environments validates the QSK50’s robust design. A construction company operating in the Canadian Arctic reported their QSK50-powered equipment starting reliably at temperatures reaching -40°F, while competitors’ machines required extensive preheating procedures. In the scorching deserts of Saudi Arabia, contractors documented continuous operation through sandstorms that sidelined other equipment, with the QSK50’s sealed components and enhanced filtration preventing dust intrusion. A demolition contractor in an urban environment noted their QSK50 engines absorbed constant shock loads from hydraulic hammers without developing the crankshaft or bearing issues they’d experienced with previous engines.

These durability advantages directly reduce maintenance burdens for construction operations. Extended service intervals—up to 500 hours between oil changes under normal conditions—minimize equipment downtime and maintenance costs. The engine’s modular design allows technicians to replace wear components quickly without complete teardowns, getting machines back to productive work faster. Construction companies report significantly fewer unplanned repairs compared to alternative engines, with some operators documenting 95% uptime rates across their QSK50-powered fleets even in the harshest jobsite conditions, translating to predictable operations and protected profit margins.

Integrated Power Pack Solutions for Construction Machinery

Cummins CCEC offers comprehensive power pack solutions that integrate the QSK50 engine with complementary systems into pre-engineered assemblies tailored for construction applications. These complete power modules bundle the engine with cooling systems, mounting frames, fuel systems, and control interfaces designed to match specific equipment requirements. Rather than sourcing individual components from multiple suppliers and managing complex integration challenges, construction equipment manufacturers and contractors can deploy fully tested, ready-to-install power solutions that reduce installation time by up to 60% compared to traditional component-by-component approaches.

The QSK50 integrates seamlessly with diverse construction machinery including large excavators, wheel loaders, material handlers, crushers, and drilling rigs. Each power pack configuration addresses the unique demands of its target application—excavator packages prioritize hydraulic system compatibility and swing load management, while crusher installations emphasize vibration isolation and continuous high-torque delivery. The standardized mounting interfaces and connection points simplify retrofitting existing equipment or specifying new machines, with plug-and-play electrical harnesses and hydraulic couplings that eliminate custom fabrication work.

Pre-packaged solutions deliver significant advantages beyond installation convenience. Factory testing ensures all components work harmoniously before reaching the jobsite, eliminating the compatibility issues that plague custom assemblies. Consolidated warranty coverage protects the entire power system rather than individual components with separate terms. Customization remains available through modular options—contractors can specify enhanced cooling capacity for extreme climates, auxiliary power takeoffs for additional hydraulic circuits, or upgraded control systems with remote monitoring capabilities. This flexibility allows construction companies to optimize their equipment for specific operational profiles while maintaining the reliability and support advantages of integrated Cummins engineering.

Cost-Effectiveness and Long-Term Value

The QSK50 Cummins delivers exceptional fuel efficiency for an engine in its power class, utilizing advanced combustion management and precision fuel injection that optimizes consumption across varying load conditions. Construction companies report fuel savings of 8-12% compared to previous-generation engines with similar output, translating to substantial cost reductions over the engine’s operational life. A fleet operator in the southwestern United States calculated annual fuel savings exceeding $45,000 per machine after switching to QSK50-powered equipment, while a European contractor documented 15% lower fuel costs per ton of material processed compared to their legacy equipment. These efficiency gains compound significantly across multi-machine fleets and extended project durations.

The engine’s exceptional longevity provides construction companies with extended service life that maximizes capital equipment investments. Many QSK50 engines surpass 20,000 operating hours before requiring major overhauls, with some documented cases exceeding 30,000 hours in well-maintained applications. This durability reduces the frequency of costly engine replacements and minimizes downtime that disrupts project schedules. A comprehensive ROI analysis conducted by a major mining contractor revealed their QSK50-powered fleet achieved 22% lower total cost of ownership over a five-year period compared to alternative engines, factoring in acquisition costs, fuel consumption, maintenance expenses, and residual equipment values.

Cummins backs the QSK50 with comprehensive warranty coverage and a global support network that protects construction investments. Standard warranties cover major components for up to three years or 5,000 hours, with extended protection plans available for high-utilization applications. The worldwide Cummins service network provides parts availability and technical expertise in virtually every construction market, ensuring rapid support regardless of project location. Authorized distributors like GRT and others provide access to genuine components and factory-trained technicians across diverse regions, helping contractors maintain their equipment to manufacturer specifications. Many contractors cite this extensive support infrastructure as a decisive factor, knowing that expert assistance and genuine components remain accessible whether operating in established markets or remote project sites, protecting both their equipment investments and project timelines.

The Strategic Advantage for Demanding Construction Operations

The QSK50 Cummins stands as the definitive engine solution for construction operations facing the harshest environmental challenges. Its combination of exceptional power output delivering up to 2,500 horsepower, reinforced durability features that withstand extreme temperatures and abrasive conditions, and intelligent engineering that maintains performance under sustained heavy loads addresses every critical demand of modern construction sites. The integrated power pack solutions simplify equipment specification and installation while ensuring optimal component compatibility, reducing deployment time and eliminating integration headaches. Beyond immediate performance advantages, the QSK50 delivers compelling long-term value through superior fuel efficiency, extended service intervals, and exceptional longevity that protects capital investments while minimizing operational disruptions.

Construction companies operating in demanding environments—from arctic cold to desert heat, from high-altitude projects to coastal humidity—consistently report improved productivity, reduced maintenance burdens, and enhanced equipment reliability when powered by the QSK50. For contractors and fleet managers seeking a dependable foundation for their heavy equipment that won’t compromise when conditions intensify, the QSK50 Cummins represents not just a component choice but a strategic advantage. Evaluate how this proven powerhouse can strengthen your construction operations, reduce total ownership costs, and provide the reliability your projects demand regardless of environmental challenges.