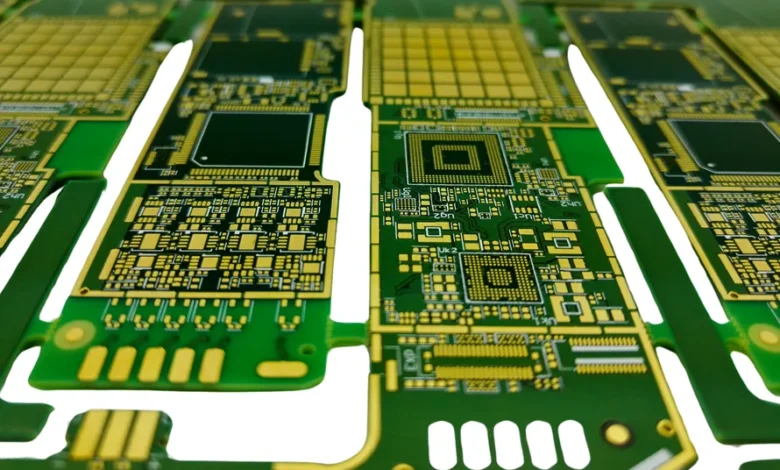

Printed Circuit Boards (PCBs) are the heart of nearly every electronic device, from consumer electronics to industrial machinery. The manufacturing process behind these boards is crucial in determining the quality, performance, and reliability of the final product. In this article, we explore the key factors to consider when selecting a manufacturer for printed circuit boards in Australia, and how PCBA services can further enhance the assembly process.

Understanding the Importance of PCB Quality

The quality of a printed circuit board directly impacts the performance of the electronic device it powers. Poor-quality PCBs can lead to a range of issues, from signal interference to product failure, which can damage a company’s reputation and increase costs due to recalls or repairs. Therefore, when choosing a PCB manufacturer, it is essential to ensure that they prioritise quality in their production process.

High-quality PCBs are characterised by excellent conductivity, durability, and resistance to environmental factors like heat and moisture. They must also meet industry standards and pass rigorous testing to ensure reliability over time. Whether you’re developing a medical device, consumer electronics, or automotive systems, a reliable PCB is key to ensuring your product functions properly in real-world conditions.

Materials and Component Selection

One of the first steps in high-quality PCB manufacturing is choosing the right materials. The material used for the substrate (typically fibreglass or resin) and the copper layer on the PCB affects both the performance and longevity of the board. For instance, high-frequency applications like telecommunications and medical devices require materials that can support high-speed data transmission without signal degradation.

In addition to the substrate, the quality of the components used in the assembly process plays a major role in determining the final performance of the product. A manufacturer that offers comprehensive PCBA services can help in selecting the right components that meet the required specifications, ensuring the integrity of the final product.

Precision in Design and Manufacturing

PCB design is a critical step in ensuring that the final product meets performance expectations. Design flaws, such as improper trace widths, incorrect component placement, or inadequate spacing, can lead to failure during the testing or usage phase. Therefore, working with a manufacturer who understands the intricacies of PCB design is crucial.

Modern PCB manufacturing relies heavily on precision and technology. Automated machines and advanced software are used to ensure that each circuit is accurately created, reducing the risk of defects. A PCB manufacturer that invests in the latest technologies can offer a higher level of consistency, leading to a more reliable product.

Testing and Quality Control

Before a PCB reaches the assembly line, it must undergo rigorous testing to ensure that it meets all necessary standards. This includes electrical testing, thermal testing, and sometimes environmental testing to simulate real-world conditions. High-quality PCB manufacturers will have stringent testing protocols in place to detect any defects early in the process.

PCBA services play a crucial role here, as they integrate the assembly and testing stages to ensure the highest quality of the final product. With quality control mechanisms, manufacturers can quickly identify problems, reduce waste, and ensure the reliability of the assembled PCB.

The Role of a Trusted PCB Manufacturer

Choosing the right PCB manufacturer is essential for achieving the desired quality, performance, and cost-efficiency. Companies like Precision Electronic Technologies offer specialised manufacturing and assembly services, ensuring that each PCB is created to the highest standards. Their experience and attention to detail make them a trusted partner for businesses looking to manufacture high-quality printed circuit boards in Australia.

With PCBA services that include everything from component sourcing to final assembly, Precision Electronic Technologies ensures a streamlined process, reducing lead times and minimising the risk of defects. Their expertise in high-performance PCBs for a range of industries guarantees that your products will meet the most stringent requirements.

Conclusion

The manufacturing process of printed circuit boards is complex and involves multiple steps, from material selection to precision design and rigorous testing. By understanding the key factors that contribute to high-quality PCB production, businesses can ensure that their products are reliable and perform as expected. Whether you’re looking for basic PCB manufacturing or comprehensive PCBA services, partnering with a trusted manufacturer like Precision Electronic Technologies can help you achieve the best results.